General Description

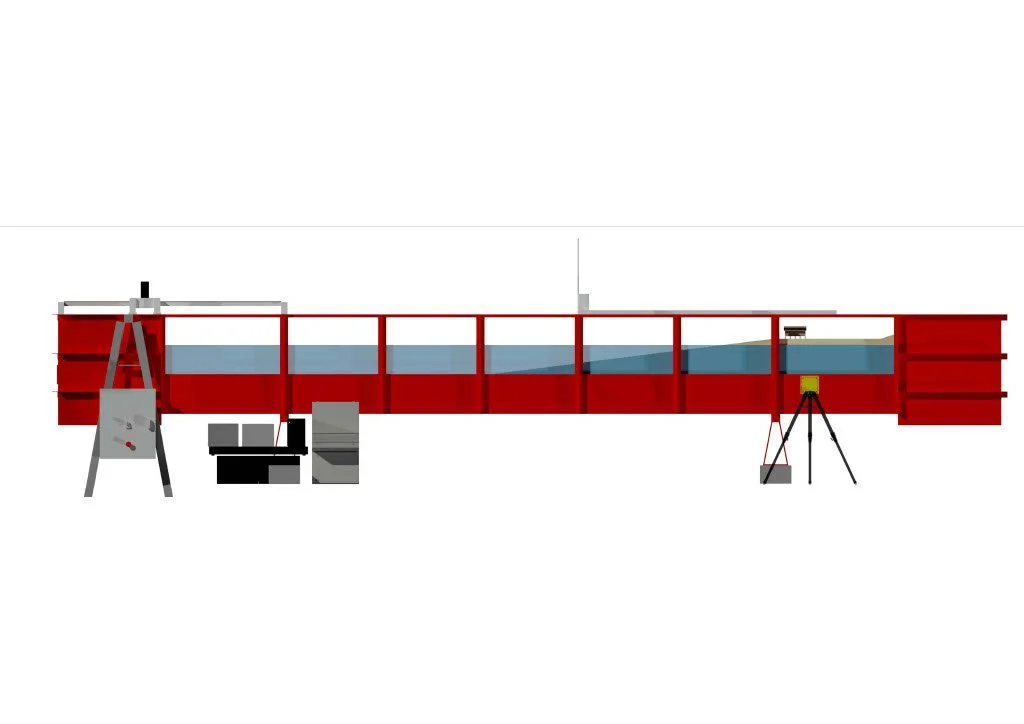

The UH wave flume was established by PI Kalliontzis and PhD student Vasileios Kotzamanis in collaboration with HR Wallingford. It consists of a steel-framed water tank with a usable length of 40 ft, a usable width of 30 inches and a usable depth of 32 inches. It has a main beach slope with an inclination of 1:8. The beach slope is specially fabricated with a foam-based material to minimize wave reflection effects. A water re-circulation system is included in the wave flume to ensure preservation of the undisturbed water level during a sequence of tests. Maximum water depth in the flume, to ensure stable testing conditions and avoid water spilling, is 20.4 inches.

Waves are generated with a piston-type wavemaker of HR Wallingford design. The wavemaker has a maximum paddle stroke of 23.6 inches. To ensure that the wavemaker is working correctly, a system of wave probes is mounted on the wavemaker to track the undisturbed water level in the flume. An active absorption system is embedded in the wave generation system to minimize wave reflection.

Wave generation is programmed with the HR Merlin software v2.50. This is a wave synthesizer program developed by HR Wallingford what can generate regular (sinusoidal), irregular, and solitary waves based on predefined functions and spectral forms. The irregular waves that can be produced by the software conform to a number of standard spectral shapes:

JONSWAP, Pierson-Moskowitz, International Towing Tank Congress (ITTC) wave spectrum, Darbyshire Coastal wave spectrum, Darbyshire Ocean wave spectrum, Neumann wave spectrum, BTTP wave spectrum, Pink (Top-Hat), Brettschneider, TMA, and Gaussian shapes. Moreover, waves can be generated based on user-defined spectral inputs.

Data Acquisition and Instrumentation of UH Wave Flume

The UH wave flume is equipped with a 3D traverser and profiler system, which is a compact multi-axis positioning system. This system is used to define the profile of the flume in three dimensions and identify the relative location and profile deformations of structure specimens before and after each test. A set of cameras for monitoring the wave flume tests is also available in the lab.

The flume is also equipped with an HR Data Acquisition and Analysis Software Program, which currently supports: eight resistive wave probes, eight HRIA-1037 high-performance pressure sensors, three uniaxial miniature (2.3 grams) accelerometers, five miniature (0.7 grams) pressure transducers, and two miniature (12 grams) compression load cells. Maximum sampling rate for the wave probes is 100 Hz, while a maximum sampling rate of 5,000 Hz is available for the other sensors.