Dr. Kalliontzis tapped for 2026 UMERC Board of Directors ||

Dr. Kalliontzis invited by SEI Houston to discuss UHPC ||

SP-I Lab student receives Paul and Helen Lenchuk Scholarship ||

Dr. Kalliontzis tapped for 2026 UMERC Board of Directors || Dr. Kalliontzis invited by SEI Houston to discuss UHPC || SP-I Lab student receives Paul and Helen Lenchuk Scholarship ||

Welcome to the Structural Performance & Fluid-Structure Interaction (SP-I) LAB!

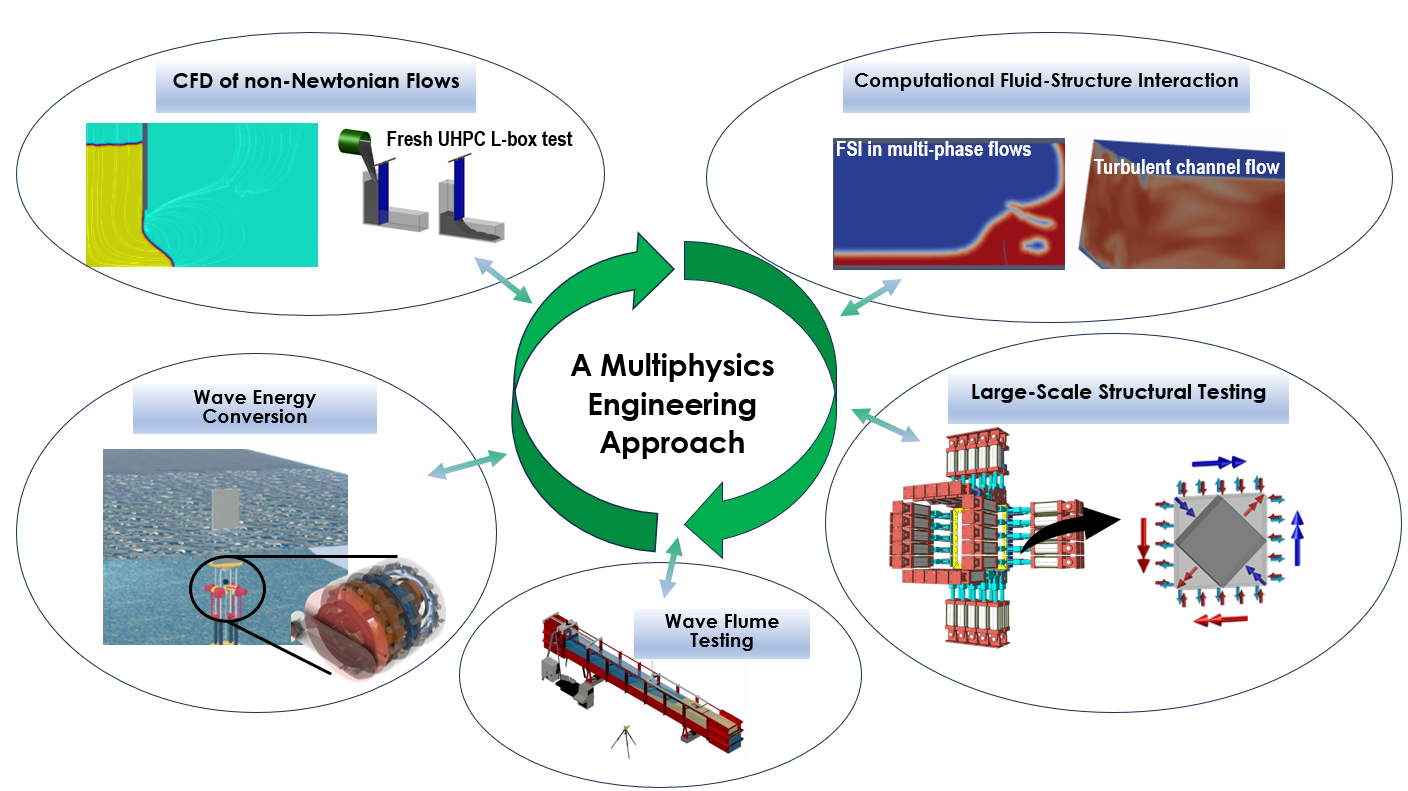

In SP-I Lab, we leverage multiphysics principles to resolve fundamental engineering problems spanning structural and fluid domains. Our research goal is to develop and investigate innovative structural and energy systems through multi-scale experimentation and computational methods.

Our planet has a finite number of resources and a growing population that overloads our aging infrastructure. These factors create the need for advanced long-lasting technologies, onshore and offshore, that deliver superior strengths, harvest energy, and minimize repair-replacement cycles. Addressing these contemporary challenges necessitates an integrated, multidisciplinary strategy. New structural systems in onshore (coastal structures) and offshore (marine energy systems) environments are exposed to extreme loads driven by natural hazards or other processes, which require a thorough understanding of fluid-structure interaction (FSI) phenomena and necessitate structural integrity.

FSI effects are omnipresent in engineering. The constitutive behavior of structural concrete technologies, such as UHPC (among other fiber-reinforced materials), is dictated by the fiber-matrix interactions during casting, which profoundly influence fiber alignment. Onshore and offshore structures and ecosystems interact with wind and wave flows, storm surge and flooding. Marine energy systems harvest the natural energy from moving water to produce power. By integrating principles of fluid and structural mechanics, SP-I’s multiphysics approach can bridge knowledge gaps and deliver comprehensive, mechanics-based solutions.

A pivotal outcome of our research is the training of a new generation of engineers uniquely equipped to re-conceptualize engineering problems by integrating multiphysics effects across fluid and solid phase states.

SP-I has initiated a campaign for the adoption of high-strength steel bars (HSRBs) by the masonry industry in the United States.

This video presents a direct tension test of a Grade 80 bar lap-splice used to investigate the bond of HSRBs in structural masonry systems.

Universal Panel Tester @ UH (UPT@UH):

The one-of-a-kind testing facility at UH, consisting of 40 in-plane and 20 out-of-plane actuators, can generate any conceivable load combination (bending, shear, torsion, uniaxial or biaxial loadings) on large-scale structural elements.

In recent years, SP-I utilized this facility to understand the constitutive shear behavior of UHPC elements.

ALE-SSM is SP-I’s in-house multiphysics computational framework. The benchmark simulation demonstrates a cantilever structure undergoing large deformations under the impact of a collapsing water column.

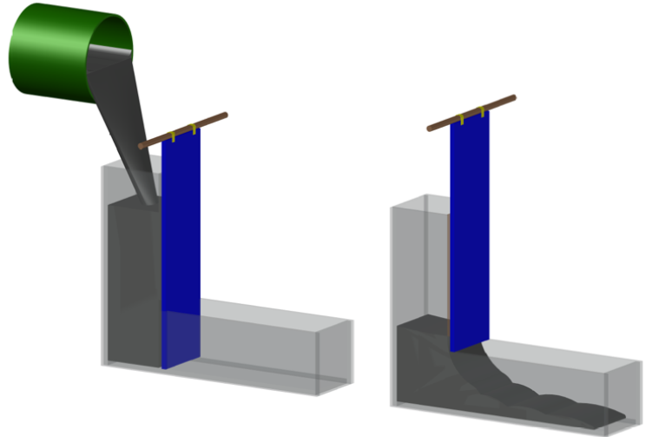

The benchmark simulation (left) demonstrates simulation of the flow of fresh UHPC in a modified L-box test setup (right). The fresh UHPC is modeled with ALE-SSM using a non-Newtonian constitutive description.