Material characterization tests at the University of Houston

The structural laboratory at the University of Houston includes an array of equipment essential for conducting various characterization tests for structural materials. Among these, three machines play a pivotal role in characterizing the mechanical properties of structural materials: the 110-kip MTS Frame and the FORNEY compression machine.

These testing machines contribute significantly to our research and educational endeavors. Whether it's evaluating the compressive strength of concrete cylinders or conducting intricate tests on Ultra-High Performance Concrete (UHPC), our testing capabilities facilitate a deeper understanding of structural materials and their behavior under various loading conditions.

110-kip MTS frame

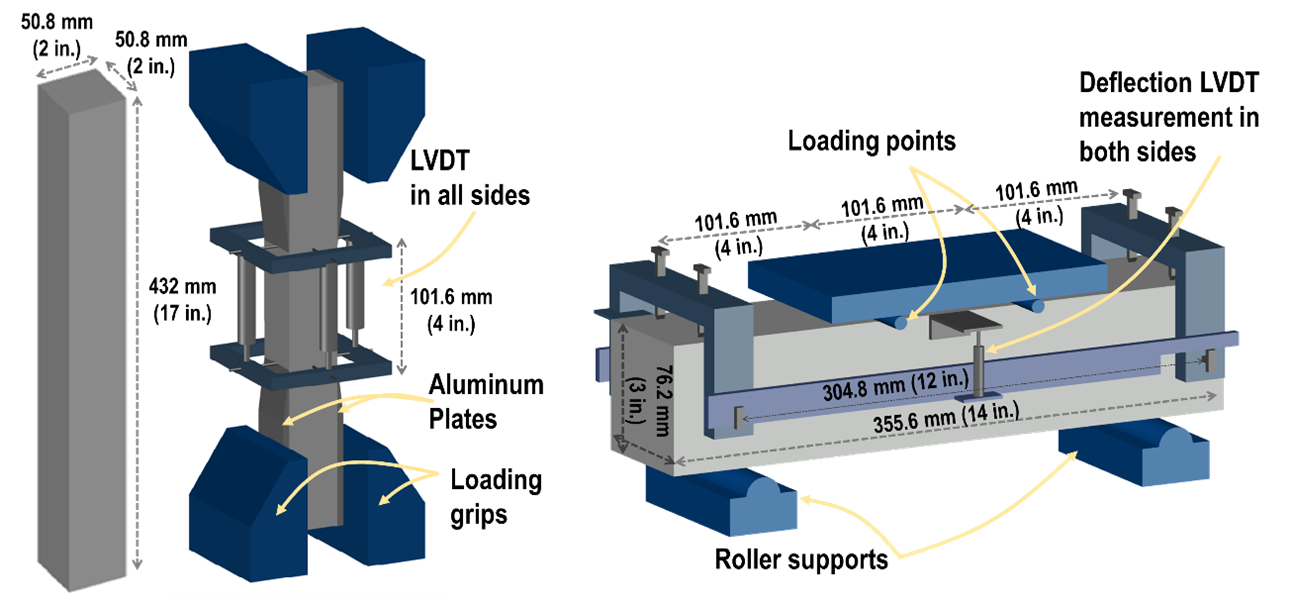

This machine is designed to apply tensile and compressive loads at various rates to a variety of specimens, allowing us to assess the strength and deformation properties of different structural materials. The 110-kip MTS Frame is particularly instrumental in conducting tests on steel coupons and concrete specimens, including direct tensile tests (DTTs) on Ultra-High-Performance Concrete (UHPC), which require precise control and measurement of tensile forces to evaluate the material's stress-strain response. The 110-kip MTS frame can also be equipped with steel beams to allow four-point bending tests of normal concrete or UHPC beam specimens.

Examples of direct tension test (DTT) and bending prism test setups at the University of Houston (Acknowledgement: Abdulrahman Salah, PhD student at the University of Houston). Beam dimensions in the figure are assumed based on fiber length < 15 mm, per ASTM C1856.

Manuals for Test Preparation and Execution

Direct Tension Test Step-By-Step Instructions (DTT)

FORNEY Compression Testing Machine

The FORNEY Compression Testing Machine is essential for evaluating the compressive strength of concrete and UHPC cylinders and cubes. The FORNEY machine can be also used to conduct flexural testing on concrete small beams.

References

ASTM C1609, ‘Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading).’ ASTM International, West Conshohocken, PA, 2019, doi: 10.1520/C1609_C1609M-19A.

ASTM C39 (2012). ‘Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens.’ Annual Book of ASTM Standards, ASTM International, West Conshohocken, PA

AASHTO T 397 (2022) ‘Standard Method of Test for Uniaxial Tensile Response of Ultra-High Performance Concrete’.

Graybeal, B.A. and Baby, F. (2019) ‘Tension Testing of Ultra-High Performance Concrete FWHA-HRT-17-053’, FHWA, U.S. Department of Transportation United States. Federal Highway Administration. Office of Infrastructure Research and Development., (No. FHWA-(February), p. 210.

Graybeal, B.A. and Baby, F. (2013) ‘Development of direct tension test method for ultra-high-performance fiber-reinforced concrete’, ACI Materials Journal, 110(2), pp. 177–186. doi:10.14359/51685532.

ASTM (2018). ‘'Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement’. American Society for Testing and Materials. A615/A615M-18. West Conshohocken, Pennsylvania.

ASTM (2015). ‘Standard Practice for Capping Cylindrical Concrete Specimens. American Society for Testing and Materials.’ ASTM C617/C617M-15. West Conshohocken, Pennsylvania.

ASTM (2017). ‘Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete. American Society for Testing and Materials.’ ASTM C1856/C1856M. West Conshohocken, Pennsylvania.

ASTM (2021). ‘Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. American Society for Testing and Materials.’ ASTM C109/C109M-21. West Conshohocken, Pennsylvania.

ASTM (2022). ‘Standard Test Method for Compressive Strength of Masonry Prisms. American Society for Testing and Materials.’ ASTM C1314-22. West Conshohocken, Pennsylvania.